Simple question, complicated answer.

I will try to answer as succinctly as possible.

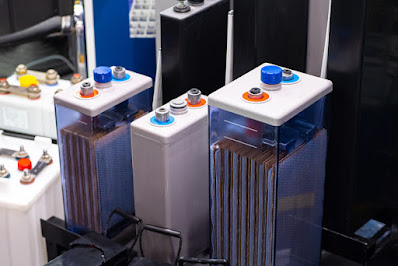

I have known sulfate crystal buildup since the invention of the lead acid battery, and this buildup handles over 70% of premature lead acid battery failures. However, all batteries wear out over time and no device can prevent this.

Over the past 30 years, battery manufacturers have made great strides in combating sulfate buildup and improving the life of their batteries by changing the construction of the battery plates, and under ideal circumstances, proper maintenance and charging, sulfation should not be a problem.

However, we don’t live in a perfect world, and sulfate buildup is still the leading cause of battery failure.

Controlled battery overcharging has been found to break down the crystals and, if used properly, keep batteries clean and extend their useful life. We do not recommend it to use this method on sealed lead-acid batteries (also known as AGM or VRLA batteries).

About 20 years ago, a simple device was developed that created high voltage pulses sent to the battery, called a pulse generator or desulfator. This device created the same effect as controlled overcharging, except that it was not regulated, so over time, these high-voltage pulses damaged the battery plates. This negated the positive effect. Circuit diagrams for this type of device are available for free on the Internet and many of the cheap devices available today are built from these designs. Short-term solution, long-term damage.

Alternative solutions were considered and experimentation showed that if a frequency pulse was sent to the battery, it could break up the sulfate buildup if the correct frequency could be achieved, however different frequencies were needed for different sizes of crystals that build up on the plates. Thus, devices using the single frequency method were and still are random, some work, some are worthless.

What we needed was a device capable of operating over a range of frequencies, voltages and battery sizes. Until the last few years, building this type of device was very expensive (over $1,000) and bulky (about the size of an old video player). Since no guarantee could be given to the end user that sulfation was the problem with their battery, no company will develop them.

The dramatic decrease in size and cost of components allowed companies to produce small, reasonably priced products capable of cleaning battery plates of various capacities and voltages.

A few manufacturers around the world are now producing products that can clean the plates of old batteries and stop the sulfate buildup on new batteries, allowing them to be reclaimed or keeping new batteries free of sulfate buildup. In fact, they can salvage many old batteries and extend the life of any battery that is not properly charged or maintained. That’s all they do, and that’s the only thing responsible manufacturers claim their desulfators can do. They can’t salvage batteries with internal damage, shorted cells or AGM batteries that have dried out.

Since it is not possible for suppliers to determine the condition or defects of the batteries on which customers intend to use the device, look for suppliers who give clear information on how to test for battery defects, or who offer a telephone or e-mail service to help you solve problems you may encounter with using a desulfator or with your specific battery configuration.

Check Our Recommendation!

EZ Battery Reconditioning is a downloadable e-book that contains informative resources on how to recondition several types of batteries. The primary purpose of this product is to help you extend the life of your electronic product batteries to save hundreds of dollars per year.

Click https://deliverit.blogspot.com/p/ez-battery-reconditioning.html for more review details.

In conclusion, modern multi-frequency desulfators are not a silver bullet to repair all faulty batteries, but they can significantly extend the life of your lead-acid batteries and recover much of the sulfated batteries that would otherwise be discarded. This significantly reduces battery replacement costs, which is not insignificant for applications such as solar storage batteries, golf carts, forklifts, large boats and motor homes.